How to set up a depot

1. What is a depot

A depot is a centralised facility for a predefined catchment area. At the depot, items are loaded onto vehicles and dispatched for delivery. And, where applicable, returned to.

In the system, if not defined otherwise, all trips start and end in the depot by default. Each depot has its own fleet, shifts, and schedules. It is the baseline element of the system.

2. How to create a depot

You create a depot through the setup page by clicking ‘Add New Depot’ as shown below.

To create a depot quickly, the standard settings are sufficient – all essential configurations are set by default. However, if you require more advanced depot customisation, you will need to access the advanced setup section.

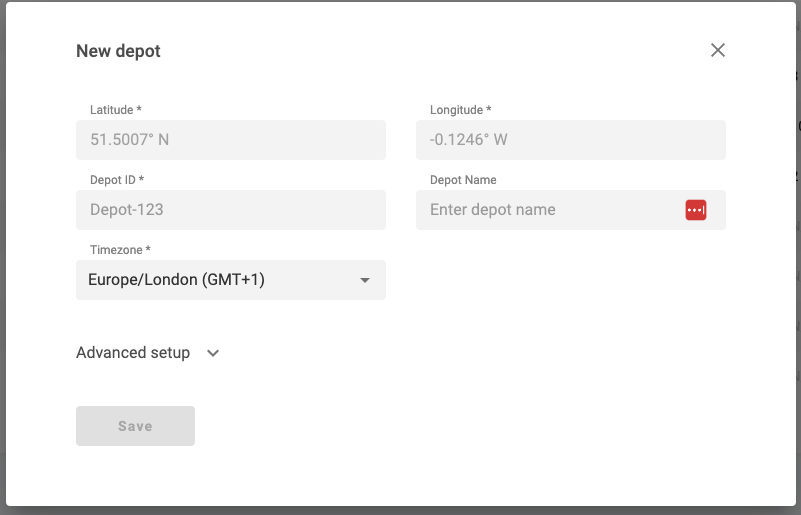

Regular settings

Regular depot settings include:

Latitude and longitude - these coordinates detail the depot's precise location.

Depot ID – this distinct identifier uniquely identifies each depot.

Depot Name - this can be the name of the depot (eg Glasgow CFC) optional field so is not required.

Time zone - each depot can be assigned its own time zone. This is essential for accurate delivery timing based on the specific region where the depot is located.

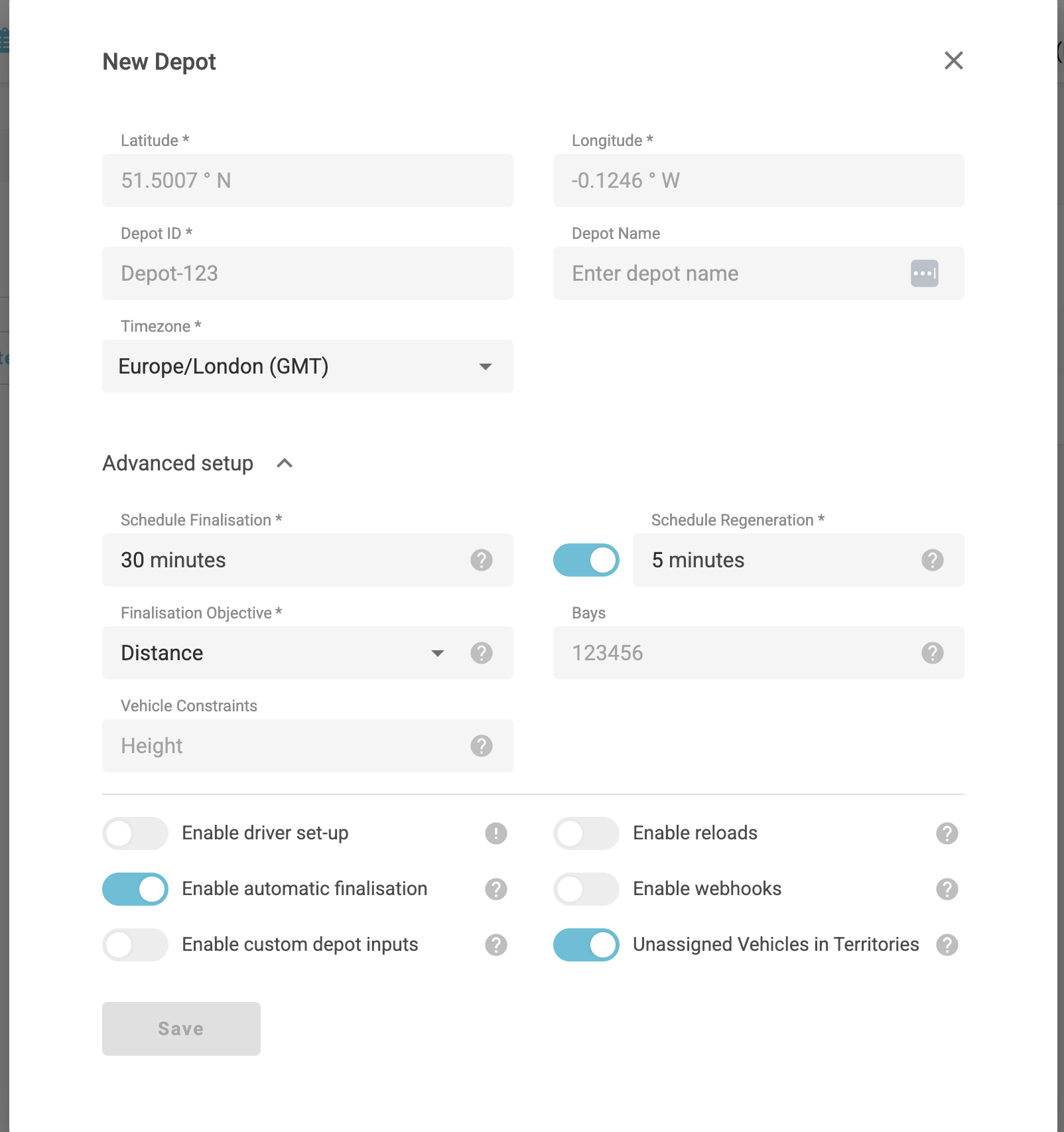

Advanced settings

Advanced depot settings include:

Schedule finalisation - this indicates the start time for the finalisation process. As an example, in the case of vehicle setup the finalisation time is scheduled for 09:00. While in the depot schedule, it is allocated a 30-minute window. This means that from 08:30 to 09:00, the trip will be in a 'prefinal' status.

Schedule regeneration - when this feature is enabled, the system proactively monitors and automatically updates the schedule in response to any changes. These changes can include adjustments for depots, vehicles, drivers, shifts, and speed profiles. For example, where a regeneration interval is set to five minutes, the system will reevaluate and update the schedule every five minutes.

Finalisation objective - defines which metric is being optimised just before schedule finalisation. For example, distance minimises the total travel distance across all trips in the depot. Duration minimises the total duration across all trips in the depot.

Bays - a designated area within a depot where vehicles are loaded or unloaded. This is a constraint that describes how many vehicles can be loaded at the same time. For example, if a depot has two loading bays and the schedule involves four vehicles with a loading time set at 30 minutes, the initial loading will accommodate only the first two vehicles. After the 30-minute interval, the next two vehicles will be loaded.

Vehicle constraints - this is a metric that quantifies a vehicle's capacity within the system. It can be customised to match specific business requirements, such as weight, tote units, cubic meters, and more. Vehicle capacity metrics are used to determine when a track is fully loaded.

Driver set-up - if this option is enabled, the depot will have the capability to create drivers and incorporate them into the schedule.

Reloads - if reloads are enabled, it indicates that the depot supports reloading. Further additional settings must be configured:

Reload latitude and longitude - the location where the reload can happen. This can either be a new location or the same depot where the vehicle initially departed.

Reload duration - the specified time period for the reload process to be completed.

Reload as break - this means that when the reload is performed, this time counts as a break for the driver.

Start time and end time - the time window during which the depot is available to accept reloads.

Automatic finalisation - enables automatic finalisation for the next day's schedule at a set time. The time must be set in the vehicle form.

Unassigned Vehicles In Territories - enabling this means that optimisation engine will use both vehicles that have been assigned to a specified territory and vehicles that are not assigned to that territory for scheduling where required for jobs within the territory. When this flag is disabled then only vehicles assigned to that territory will be used for order scheduling.

Enable webhooks – allows webhooks to be sent. Further additional settings are required:

URL - address where we will send updated execution plans based on location pings and completion events.

ETA interval - a time is set for how often the updated execution plan is sent.

Header key - key that is included in the headers when sending a request.

Header value - value that is included in the headers when sending a request.

Enable updates – you can choose whether to send full execution plans or only the trips that have changed.

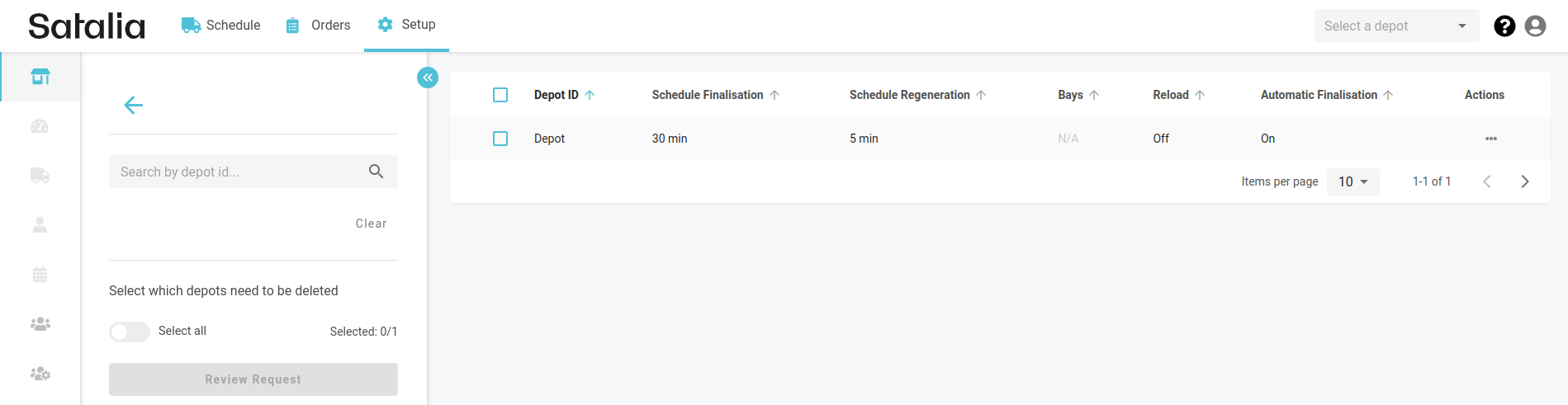

3. How to delete a depot

You can delete depots. But it’s important to note that this action will result in all associated information being removed too. This includes depot vans, drivers, schedules, and more.

It’s also not a straightforward process, and requires administrator access to the eraser API.

To start, head to the setup page. Click the 'Request Delete' button, then choose the depot or depots you wish to delete.

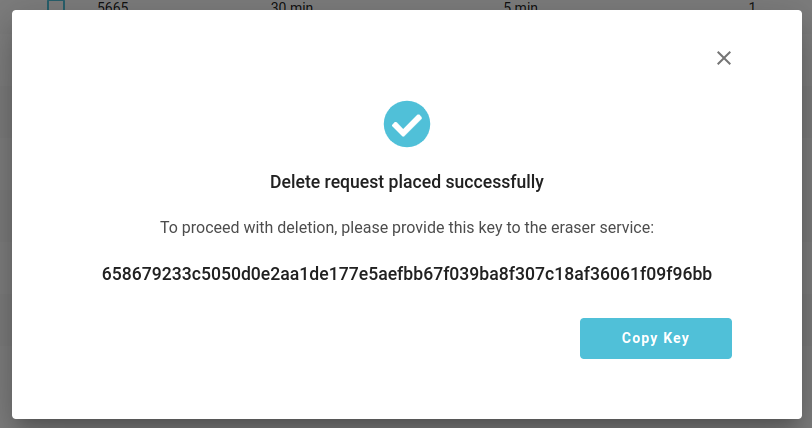

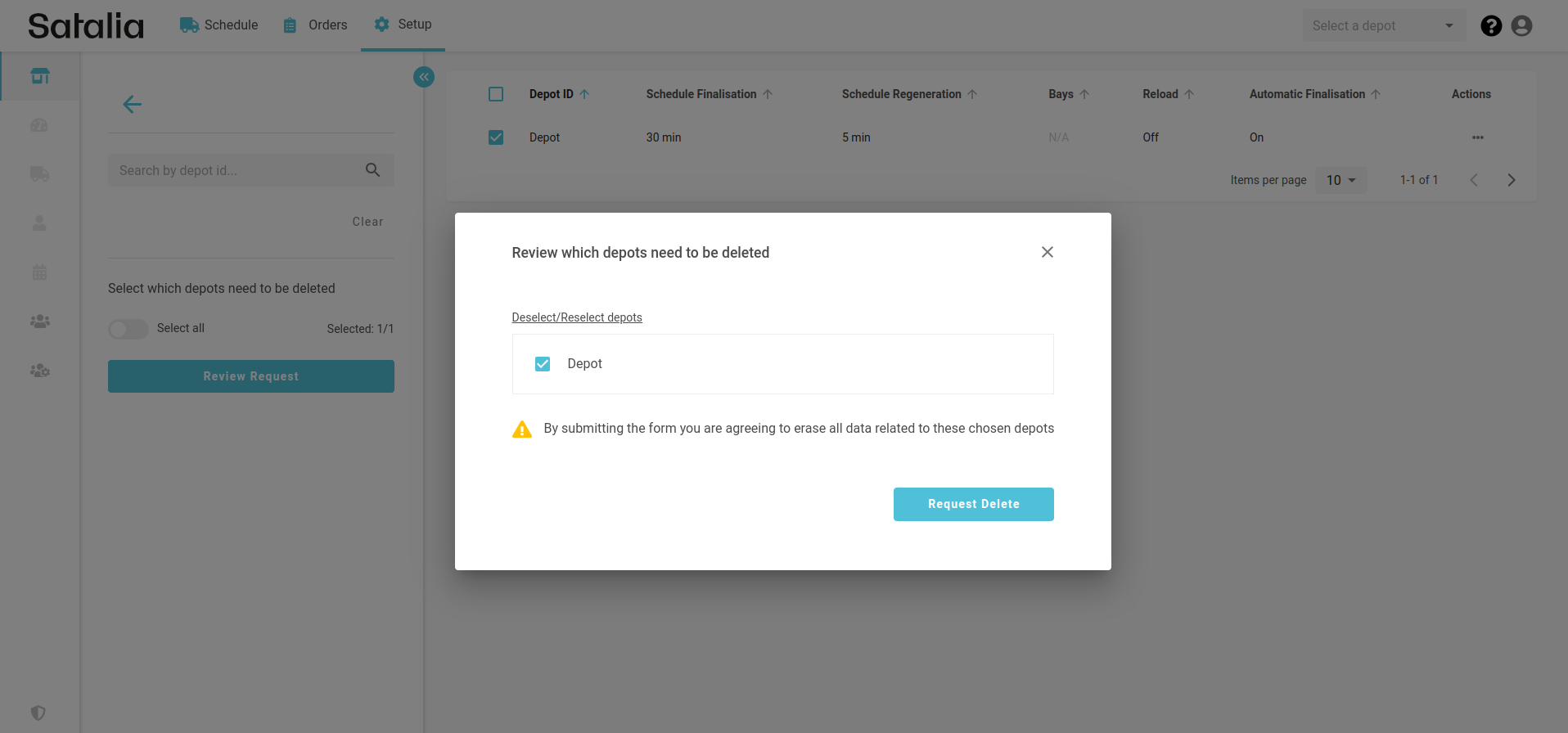

After selecting the depot you wish to delete, click on 'Review Request’. A modal will appear displaying all the relevant details.

If all the details are correct, click 'Request Delete’. The deletion process will then start.

Copy the key and send it to the administrator to proceed with the deletion of the selected depot or depots. The key can be copied by clicking the ‘Copy Key’ button.